What We Do

We work in partnership with customers to solve their biggest operational challenges safely, efficiently and sustainably.

Our board of directors inspires, motivates and guides the organisation to greater success by defining new and exciting horizons to scale. Senior leadership, comprising eminent industry experts who bring a wealth of knowledge, works to achieve the vision and mission of the organisation by setting high standards of performance and excellence. Founded in 2006, DVGR engineers solutions that improve safety, efficiency and sustainability - helping to provide the essential resources needed by a growing world.

We work in partnership with customers to solve their biggest operational challenges safely, efficiently and sustainably.

Our vision is to be the most admired engineering business in our markets.

Read more on Weir's ambitious sustainability roadmap and how we are embedding sustainable practices at the heart of our business.

We work in partnership with customers to solve their biggest operational challenges safely, efficiently and sustainably.

Our vision is to be the most admired engineering business in our markets.

Read more on Weir's ambitious sustainability roadmap and how we are embedding sustainable practices at the heart of our business.

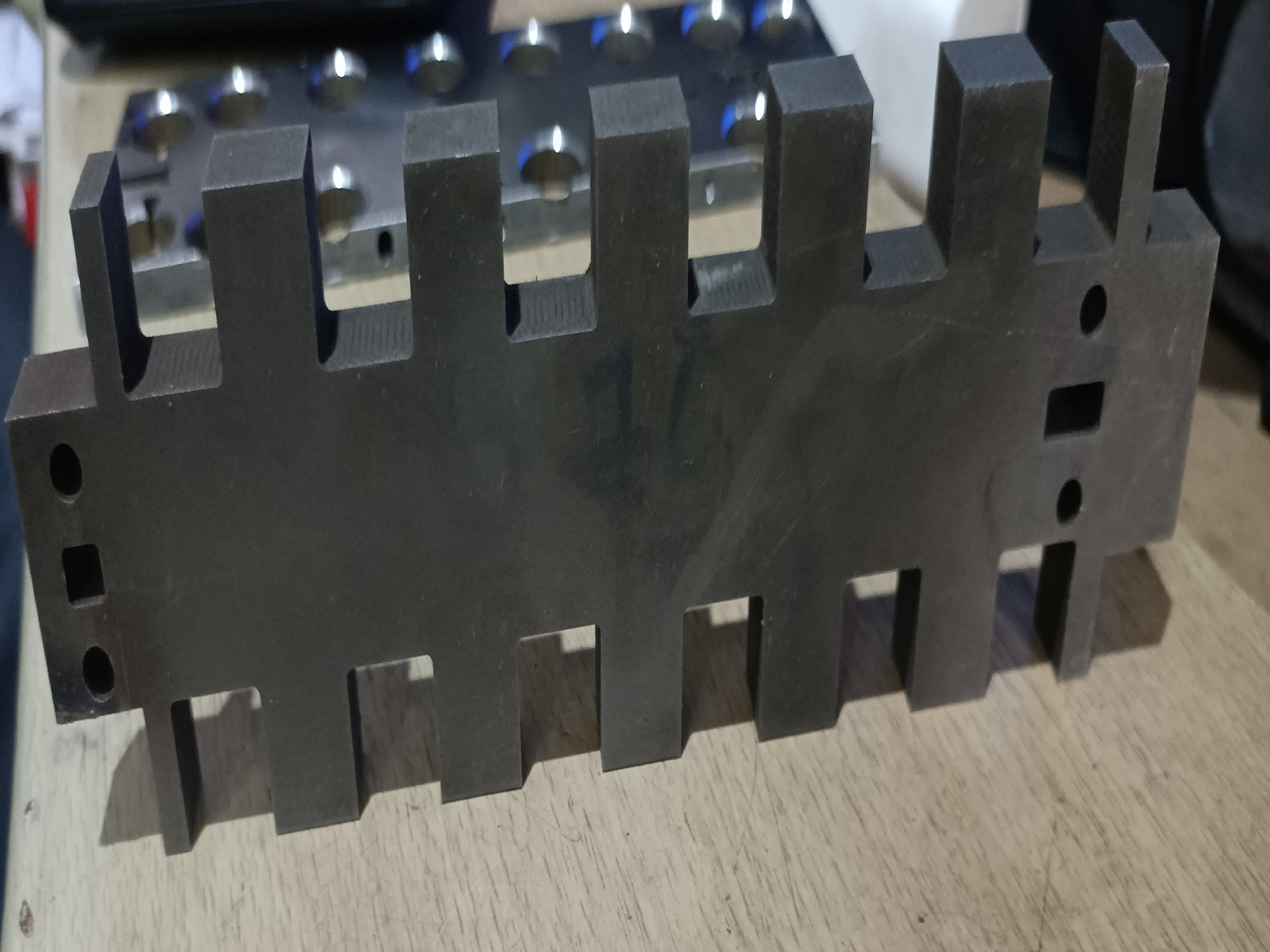

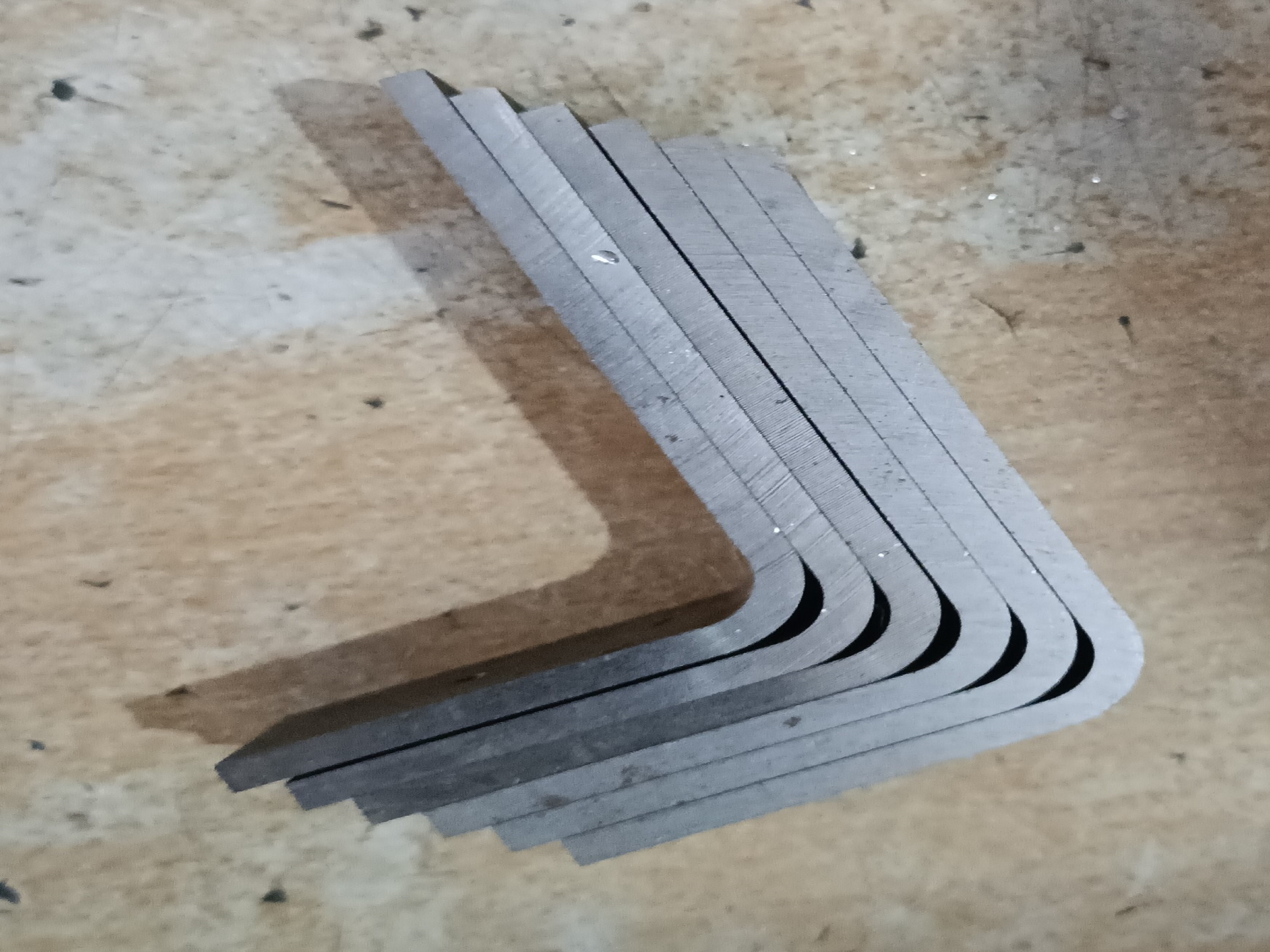

DVGR machining is the process of creating a shape with electrical current discharges between two electrodes – the tool and the workpiece. Rapid electrical discharges pass between the tool and the workpiece, removing small amounts of material that is flushed away

DVGR services are effective at machining hard metals that may require intricate precision, as material hardness is not a factor. As the name suggests, electrical discharge machining is only applicable to materials that are electrically conductive. KLH offers multiple DVGR services, categorized by the type of tool-electrode:

KLH sinker burns any electrically conductive material, whether soft or hard, without inducing stresses into the material. CNC-controlled sinker DVGR services are an ideal low risk machining solution for dies, molds, or any piece with preexisting machine or labor hours. Sinker DVGR is for companies looking to minimize machining risk with reliability and accuracy.

Sinker DVGR (also referred to as conventional or ram DVGR) utilizes a custom-made electrode that “sinks” a shape into a material. Electrodes – which are commonly made of graphite, copper, or tungsten – appear as a reverse, or negative, of the required shape. As with all DVGR services, the tool-electrode degrades with use, which requires additional electrodes for long-run sinker applications.

The quality lab can be a stressful stop in the manufacturing process: critical dimensions, key features, and final inspections. The pressure can be overwhelming, but inside KLH’s temperature- and humidity-controlled quality lab, it's tough to break a sweat. As part of a fully equipped quality lab, KLH utilizes multiple contact and vision CMM systems to provide accurate, precise measurements. These measurements include third party inspection (in-process or final), first article inspections, statistical analysis, capabilities studies, and reverse engineering.

.jpg)

45

165

563

245

No.107/7, 2ndBlock, Peenya, behind Shanimahathma Temple, 3rd Cross, Pennya Industrial Estate, Bangalore - 560058

+91 9738110847

Mon-Sat 09:00 AM - 07:00PM